Workshop Scheduling Board Kit Systems

Workshop Scheduling | Garage Planning | Auto Maintenance

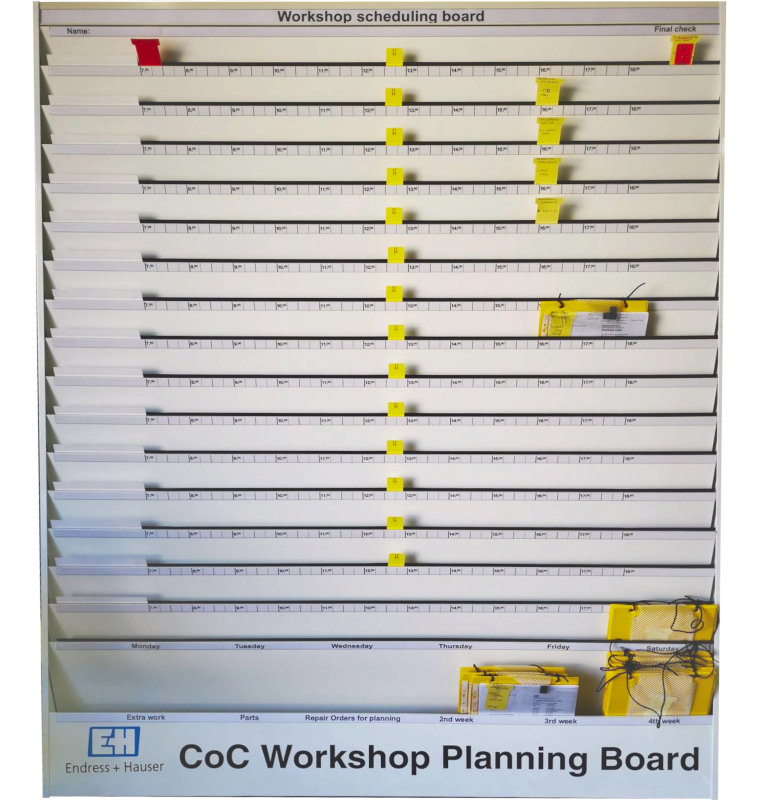

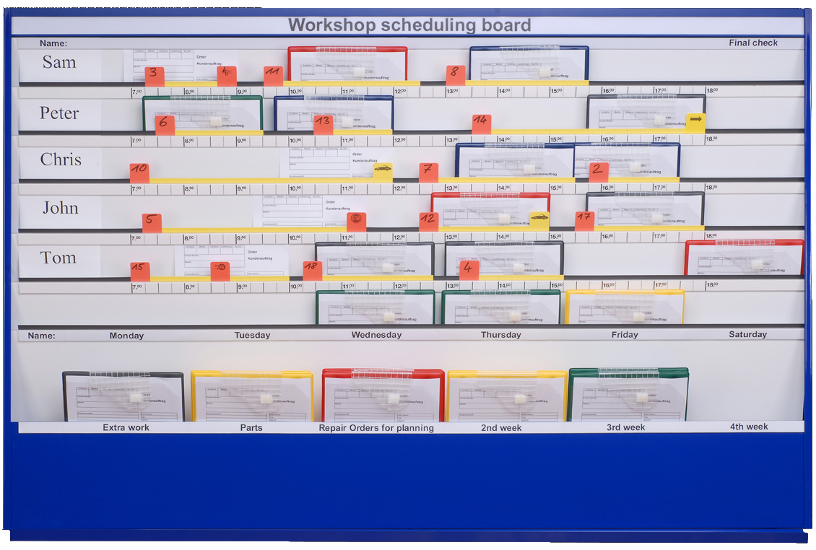

Workshop Scheduling Boards are the ideal solution for workshop job loading & scheduling. Durable scheduling rows with integrated time strips enable A4 or A5 job orders to be quickly, simply and efficiently allocated to technicians / workstation whilst clearly displaying planned completion time and any special job requirements. This intuitive and highly visible method of planning maximises workshop efficiency, increase productivity and enables clear identification of spare capacity

The Workshop Scheduling Boards operate on a simple, highly visual, rapidly updated and intuitive planning principal

Jobs are allocated to specific workshop technicians or workstations through simple placement of the job order paperwork to the respective workstation row. The right hand edge of the job order aligns with the integrated date/time scale strips identifying the planned completion time

On job commencement the designated technician removes the job order, leaving the scheduling copy on the board to signify job commencement and planned completion time

Following completion, the scheduling order and job order are placed in the “Final Inspection” column for quality control purposes

Once the job order has passed the final inspection an invoice can then be generated

Eurocharts offer three Workshop Scheduling Board models dependent upon specification and budget. Each model is available in a selection of workstation capacities (number of rows)

MK1 - The complete scheduling solution (Metal Frame)

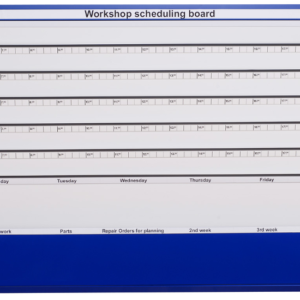

MK2 - The simplified board for less complex requirements (Metal Frame)

MK3 - The economical & versatile board (Polypropylene)