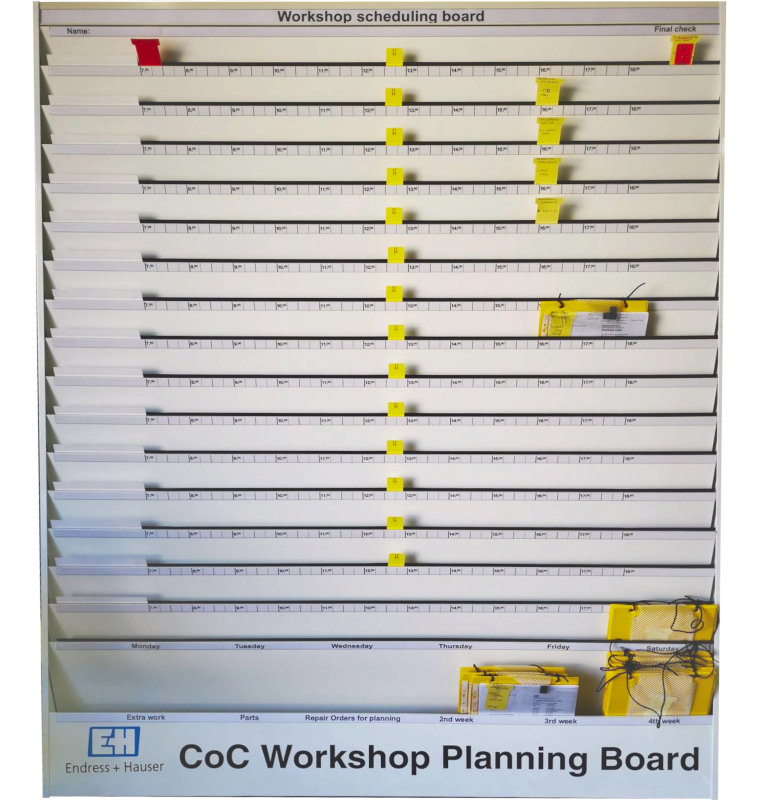

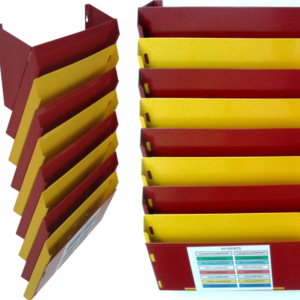

MK1 Workshop Scheduling Board

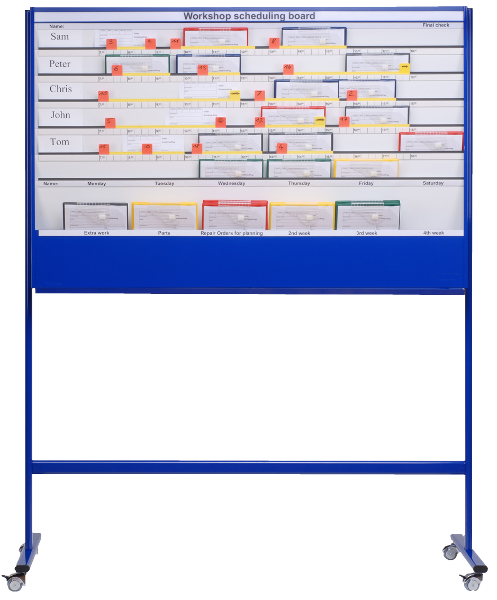

The MK1 Workshop Scheduling Board is the complete workshop planning solutionIn addition to the highly visual and precise scheduling ability that is the trademark of all Workshop Boards, the MK1 offers enhanced planning features that are unique to this model

| • | Future Planning Capacity - Monday to Saturday slots to schedule orders for the following week, with additional single compartments for 3 week forward loading |

| • | Work On Hold - Allocated job card compartments for Sub-contracted, Awaiting Parts & Jobs on Hold |

| • | Precision Scheduling - Visualise the complete job order duration with yellow time strips. The strips insert into the integrated time scale channel of the MK1 workshop board, displaying the scheduled job duration. Absence of time strips indicate spare capacity |

| • | Job Information Icon cards - Inserted into the integrated time scale channel of the MK1 workshop scheduling board to illustrate specific order requirements. For example, pool car, job over-run or any activity affecting job status |

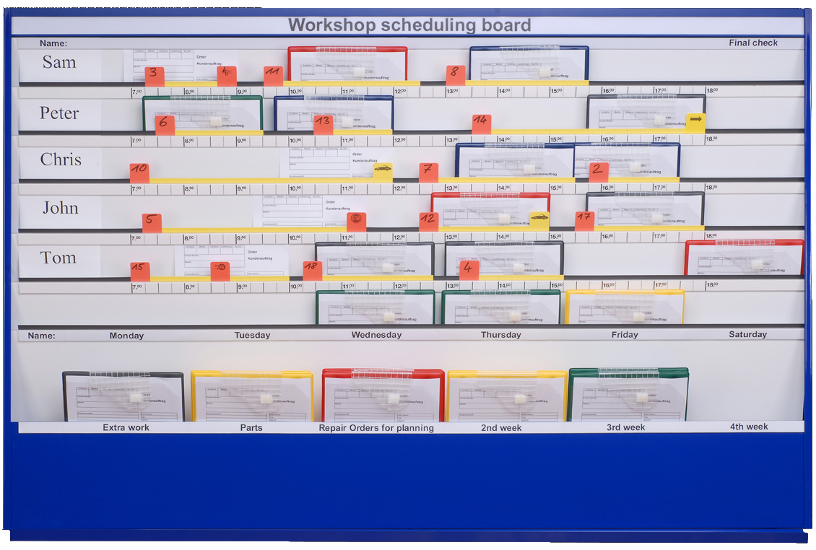

The Workshop Planning Boards operate on a simple, highly visual, rapidly updated and intuitive planning principal

Jobs are allocated to workshop technicians or workstations through placement of the job order paperwork to the respective workstation row. The right hand edge of the job order aligns with the integrated date/time scale strips identifying the planned completion time

On job commencement the designated technician removes the job order, leaving the scheduling copy on the board to signify job commencement and planned completion time

Following completion, the scheduling order and job order are placed in the “Final Inspection” column for quality control purposes

Once the job order has passed the final inspection an invoice can then be generated