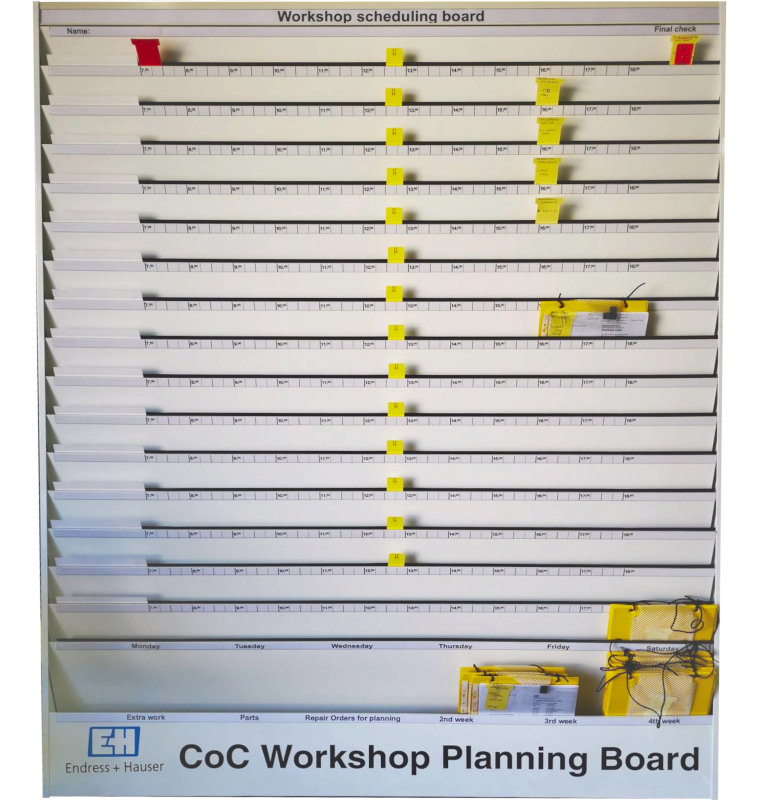

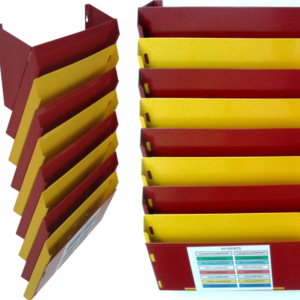

MK2 Workshop Scheduling Boards

The simplified board for less complex planning requirements compared to MK 1 Workshop BoardsA popular and powerful auto maintenance scheduling tool, available in multiple workstation capacities

The powder coated metal framed MK2 workshop board has been simplified by removing the additional planning features of the MK1 Workshop Board but retains the highly visual and precise planning ability that is the trademark of all Workshop Scheduling Boards

Similar in construction to the MK1 but without the advanced planning capacity, utensil tray, icon/time strip capacity or printed board title strip

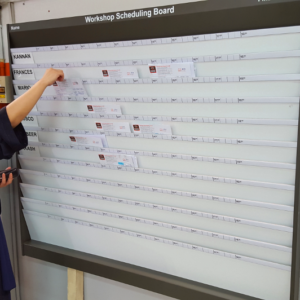

The Workshop Planning Boards operate on a simple, highly visual, rapidly updated and intuitive planning principal

Jobs are allocated to workshop technicians or workstations through placement of the job order paperwork to the respective workstation row. The right hand edge of the job order aligns with the integrated date/time scale strips identifying the planned completion time

On job commencement the designated technician removes the job order, leaving the scheduling copy on the board to signify job commencement and planned completion time

Following completion, the scheduling order and job order are placed in the “Final Inspection” column for quality control purposes

Once the job order has passed the final inspection an invoice can then be generated